Customer Submitted Project:

Composter using the CCS C Compiler

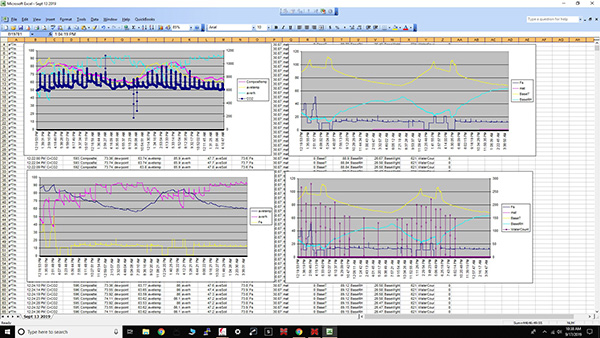

Resources Used - CCS C Compiler, Excel, bootloader and Putty. I made a lot of the tools and displays myself.

It's easy to make any compost. There are many applications for compost, for example, plant disease suppression and supplementing soils with the correct micro biology for plants to thrive. Making good compost is a huge learning curve and is somewhat black magic. This machine takes the black magic out of making supplemental compost and disease suppression compost(s).

After fluffing static composts piles for 15 years, I wanted something automatic that I knew would create compost constancy while using microscopes to monitor the compost quality. I'm tired of turning compost piles. I got an off-the-shelf turning drum composter and added a motor. Not trivial to do. The trick to making good compost is not letting it go anaerobic. Key gas measuring sensors are in place to check for anaerobic gasses.

Microprocessors made it easy to collect data on a PC. By monitoring the data when I'm not looking at the compost machine, I can see what changes happen. Most of the action is in the concentrations of gasses we can't see.

Sensors are not trivial to make or to interface. There are a lot of environmental issues with sensors where the RH can cause a "RH and temperature I2C chip" to fail when it is above 85%. Dirt getting into the sensors also makes a lot of trouble. I had to test many sensors before putting them into the composting drum. Having CCS compiler routines already built, made the board "bring up time" shorter. CCS C is a really easy platform to get started on CPUs. I lay out boards too. It's easy to split between FW, Analog, RF and HW. Yes, I'm using RF for sending serial data from the drum to the base CPU. Since I have been doing embedded programming for decades, I have a huge library of routines where I can cut and paste from one project to another. The same is for the sample programs given by CCS. I have borrowed a lot of programs from the provided examples. There are a lot of issues with I2C, SPI, RS485 and RS232 communications with just communicating to new devices (addresses, commands, parsing data and the rest) that take a lot of time. This compiler gets rid of a layer of communication I don't have to fuss with.

The new sensors added are H2S, ppO2, CH4 and RH in compost. Right now it does CO2, RH, Temp, Compost Temp, drum weight, outside RH and temp. Depending on the measurements of these gasses and the position in the script composting decomposition cycle, it will tell the composter what to do. It turns out that making usable compost has similar skills as making a fine wine. Because of the instrumentation and the firmware, it's possible to data log recipes for different composts.

It turns out it is possible to make the embedded CPU take a made up programming language and run as if it is native code. The computer language is used to run the composting machine and it totally runs in the Microchip CPU.

This composter is used for universities for research and for land revitalizing for farms that destroyed soil by chemical fertilizers and pesticides. It's basically a super-programmable HALT chamber.